Purpose

The overall purpose of the course is to provide practical training in bolt tightening and shimming techniques and tools specific for the purpose through the use of different types of exercises performed individually and/or in small groups the ability to safely and competently perform torquing and tensioning of bolts as well as shimming are achieved.

The course is a combination of theory and practical training, so we ensure both an understanding of the mechanisms involved, and why the necessary precautions should be taken, just as it is important to understand torque tensioning itself from a purely practical point of view.

Target Audience

Engineers / Technicians who will be involved in the use of hand, hydraulic torque and tensioning equipment.

BOLT TORQUING

Course Content – 4 Hrs

• What is torque?

• Why it is preferred for bolt tightening?

• Bolt torque for flange joint assembly

• Stress-strain curve

• Forces on a bolted flange

• K Factor-Importance of lubricant

• Factors affecting torque values

• How much Bolt Load should you apply?

• Bolt Torque calculation

• Manual torque wrench

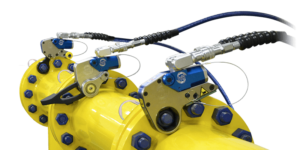

• Hydraulic torque wrench and it’s components

• Hydraulic Bolt Tensioning

• Hydraulic bolt tensioner

• What is gasket?

• How does gasket prevent leakage?

• Gasket specification

• Types of gaskets

• Should we apply grease on a RTJ gasket?

• Chemical resistance chart

• Installation of gasket

• Alignment of flanges

• Consequences of gasket failure

• Gasket installation

• Bolt tightening sequence

• Things to avoid while installing gasket

• Why studs are preferred over bolt in flanged joints?

• Latest development in bolt torquing

• Why it is preferred for bolt tightening?

• Bolt torque for flange joint assembly

• Stress-strain curve

• Forces on a bolted flange

• K Factor-Importance of lubricant

• Factors affecting torque values

• How much Bolt Load should you apply?

• Bolt Torque calculation

• Manual torque wrench

• Hydraulic torque wrench and it’s components

• Hydraulic Bolt Tensioning

• Hydraulic bolt tensioner

• What is gasket?

• How does gasket prevent leakage?

• Gasket specification

• Types of gaskets

• Should we apply grease on a RTJ gasket?

• Chemical resistance chart

• Installation of gasket

• Alignment of flanges

• Consequences of gasket failure

• Gasket installation

• Bolt tightening sequence

• Things to avoid while installing gasket

• Why studs are preferred over bolt in flanged joints?

• Latest development in bolt torquing

BOLT TENSIONING

Course Content – 4 Hrs

• Overview of offshore oil & gas installation

• Bolted joints

• Flanged joint

• Components of flanged joint

• Studs & Hex Bolts

• Bolt material guide

• Bolt thread

• Bolt coating/ plating

• Bolt specification & identification

• Improper joint – THE BOLTS ARE TOO SHORT!

• Washers

• Manual Bolt Tightening

• Manual Bolt Tightening Procedure

• Leaking flange & bolt tightening

• Hot bolting

• Restrictions on Hot Bolting

• Problems & corrective measures

• Flange spreader

• International standard for flange material & dimension

• Pressure classes of flange

• Types of flanges

• Butt weld flange versus fillet weld flanges

• Flange facing

• Flange pressure/ temperature rating

• Flange specification

• Flange identification

• Pipe flanges Do’s and Don’ts

• Bolting Do’s and Don’ts

• Points to be taken care of while dismantling/ assembling flanged joints

• Bolted joints

• Flanged joint

• Components of flanged joint

• Studs & Hex Bolts

• Bolt material guide

• Bolt thread

• Bolt coating/ plating

• Bolt specification & identification

• Improper joint – THE BOLTS ARE TOO SHORT!

• Washers

• Manual Bolt Tightening

• Manual Bolt Tightening Procedure

• Leaking flange & bolt tightening

• Hot bolting

• Restrictions on Hot Bolting

• Problems & corrective measures

• Flange spreader

• International standard for flange material & dimension

• Pressure classes of flange

• Types of flanges

• Butt weld flange versus fillet weld flanges

• Flange facing

• Flange pressure/ temperature rating

• Flange specification

• Flange identification

• Pipe flanges Do’s and Don’ts

• Bolting Do’s and Don’ts

• Points to be taken care of while dismantling/ assembling flanged joints

Bolt Torquing & Tensioning

| Course | Fee INR | Duration | Course Timing | Date Commence | Remarks |

|---|---|---|---|---|---|

| Bolt Torquing | 7,000 | 1/2 day | 10:00 | On Demand | Practical Workshop |

| Bolt Tensioning | 7,000 | 1/2 day | 10:00 | On Demand | Practical Workshop |

| Both Combined | 12,000 | 1 day | 10:00 | On Demand | Practical Workshop |

BOLT TORQUING & TENSIONING was last modified: July 1st, 2023 by admin